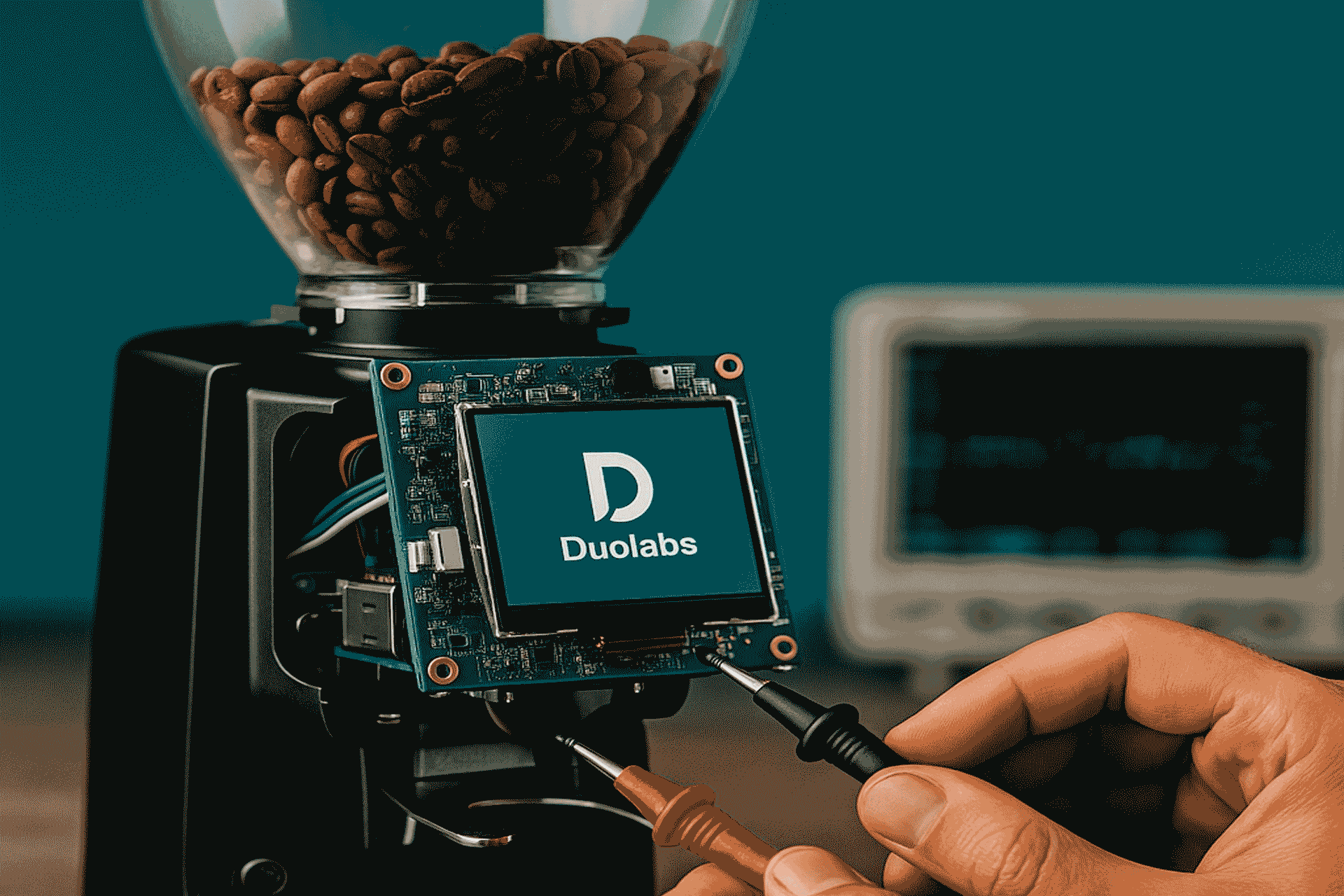

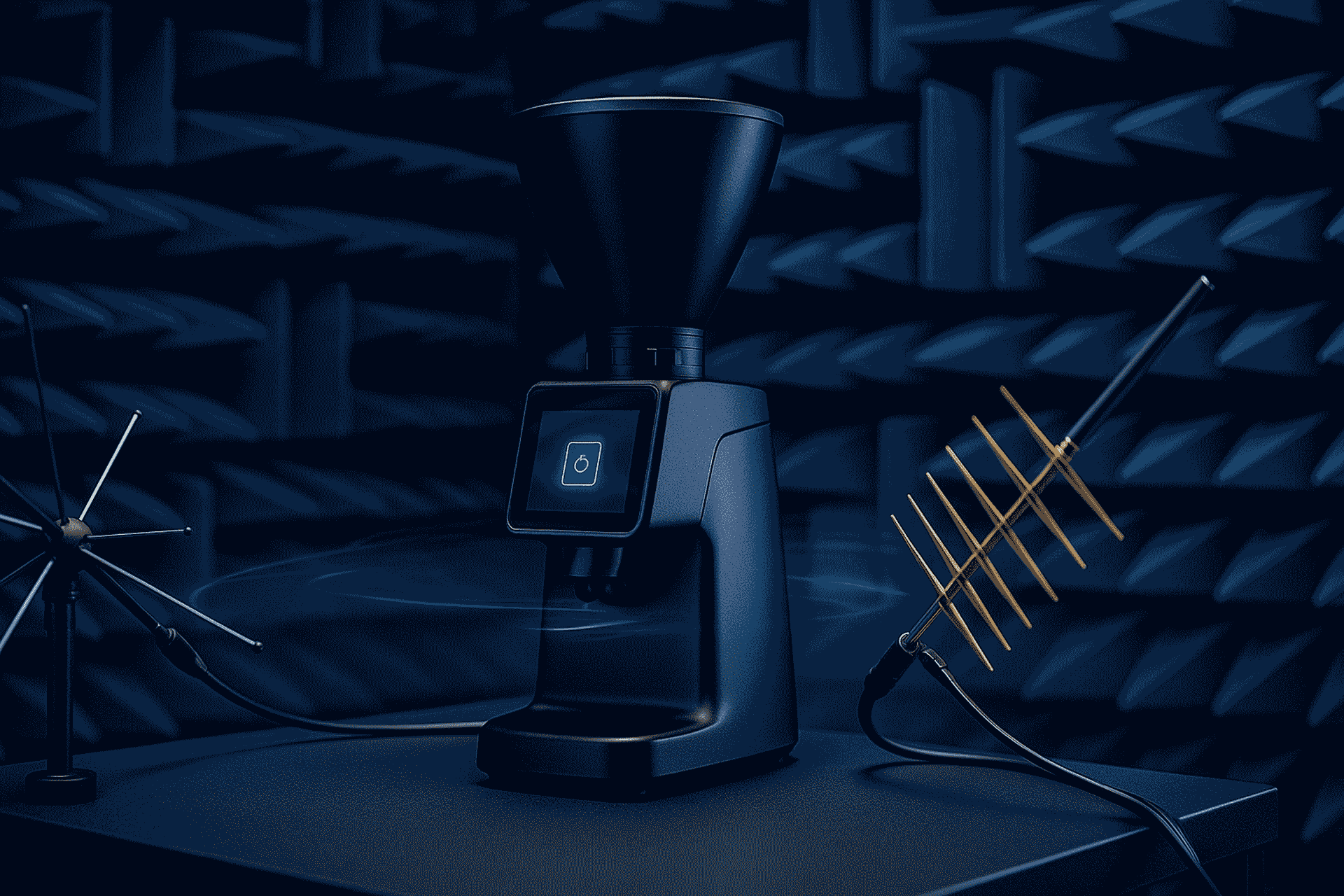

Idea

We co-design the idea with the client from the very beginning. We bring in our specialist skills (hardware, firmware, software, AI, Cloud IoT) to provide a complete framework and identify solutions that aren’t immediately obvious. Hands-on experience allows us to turn intuition into concrete choices, reducing risk, time and cost, and steering the project toward a scalable, competitive outcome.

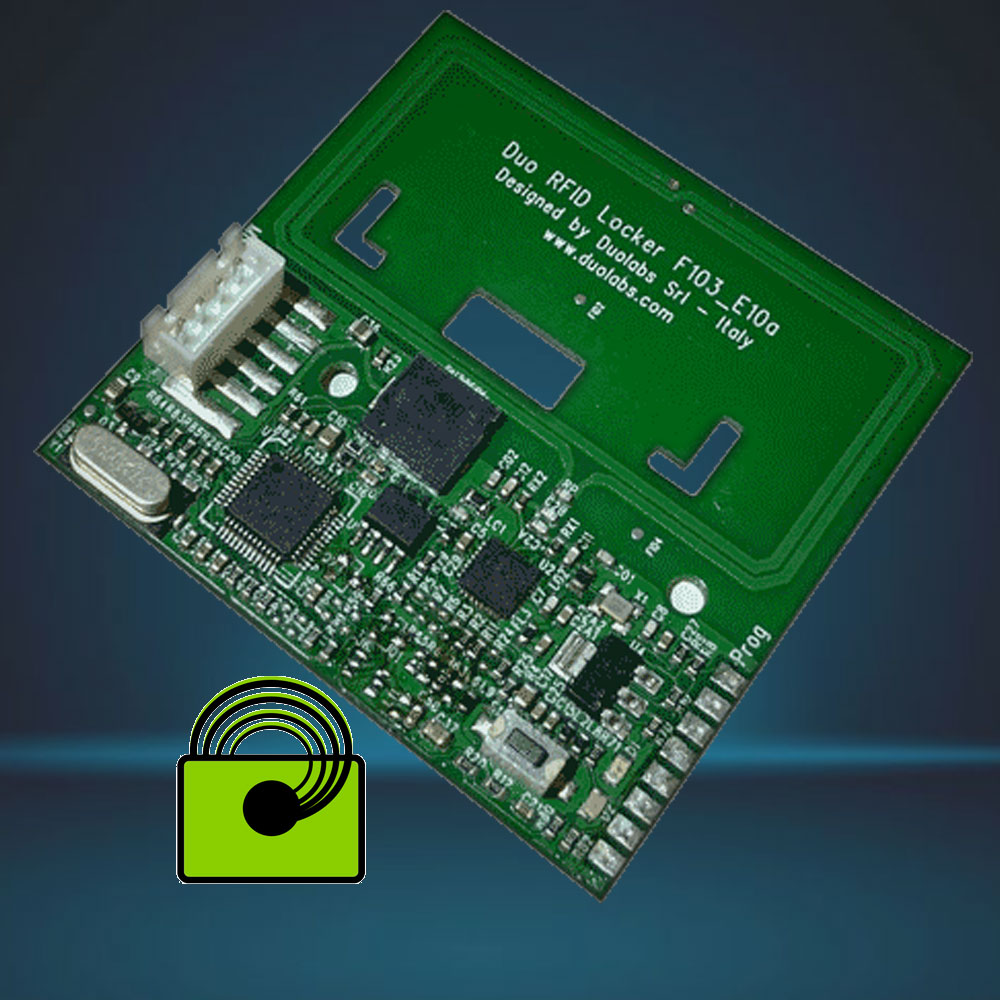

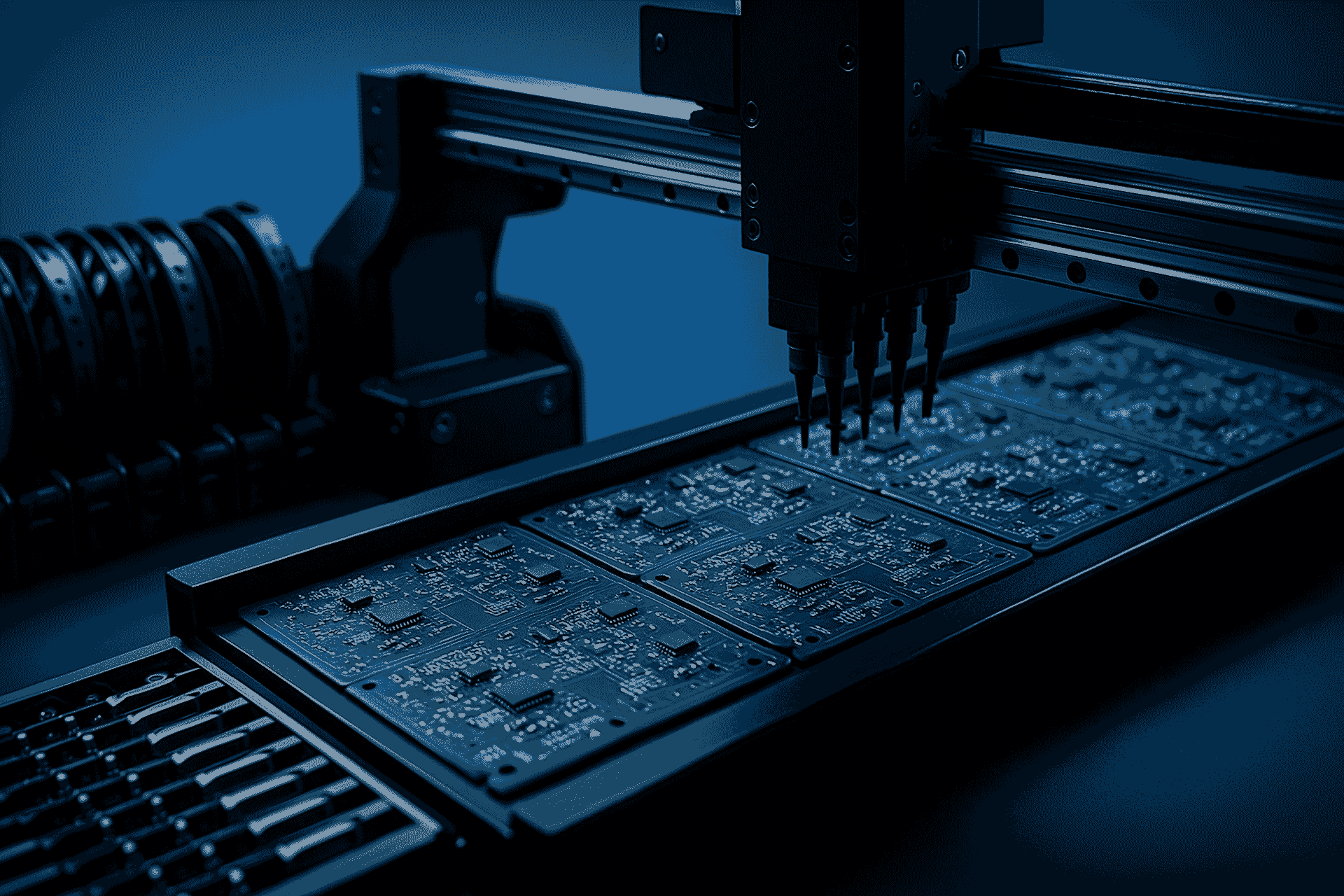

Drafting the specifications

We draw up complete specifications for the final product in all its parts and components: functional and performance requirements, architecture, hardware, firmware, software/app, interfaces and protocols, tests and validation, regulatory compliance, and documentation for production and maintenance.

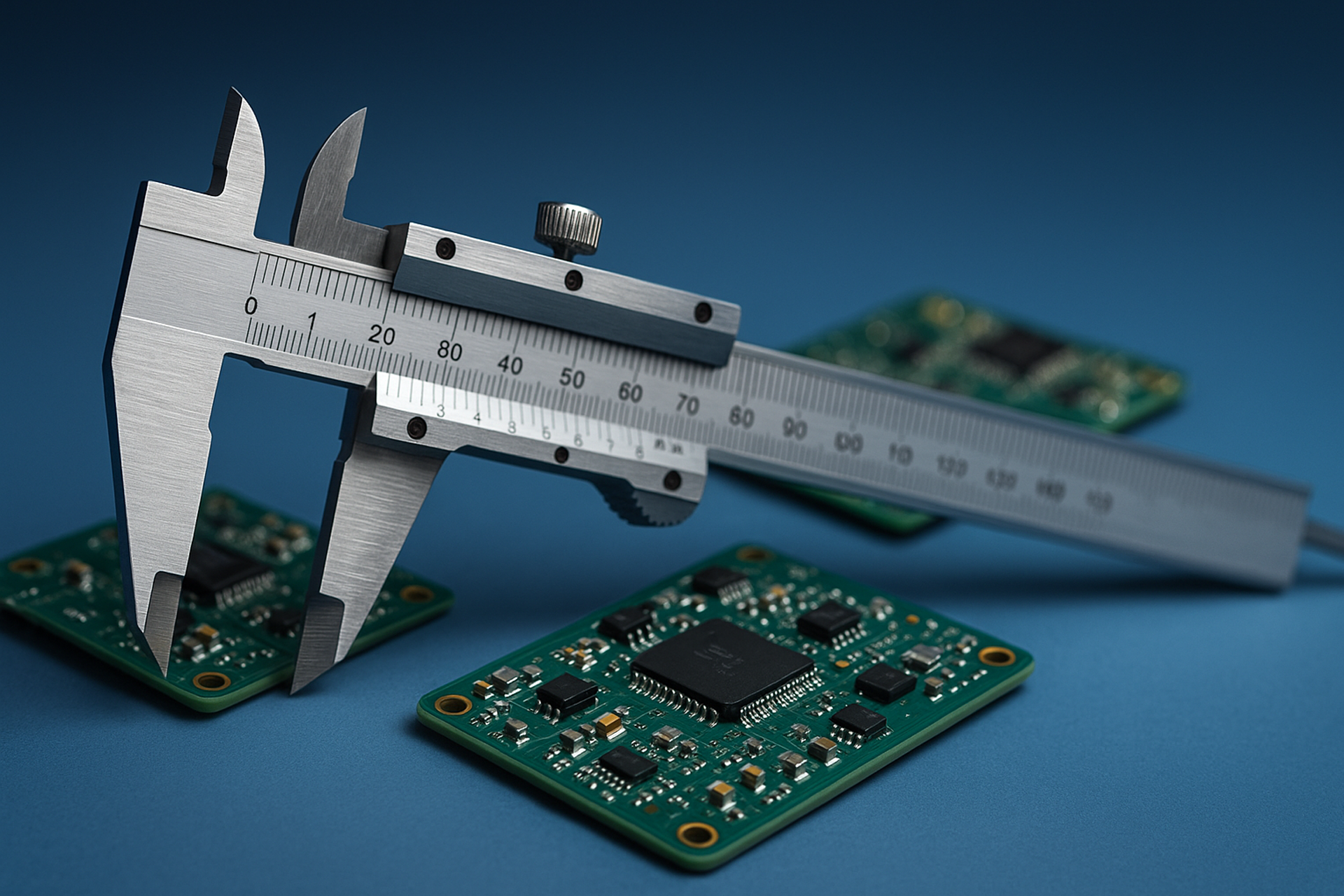

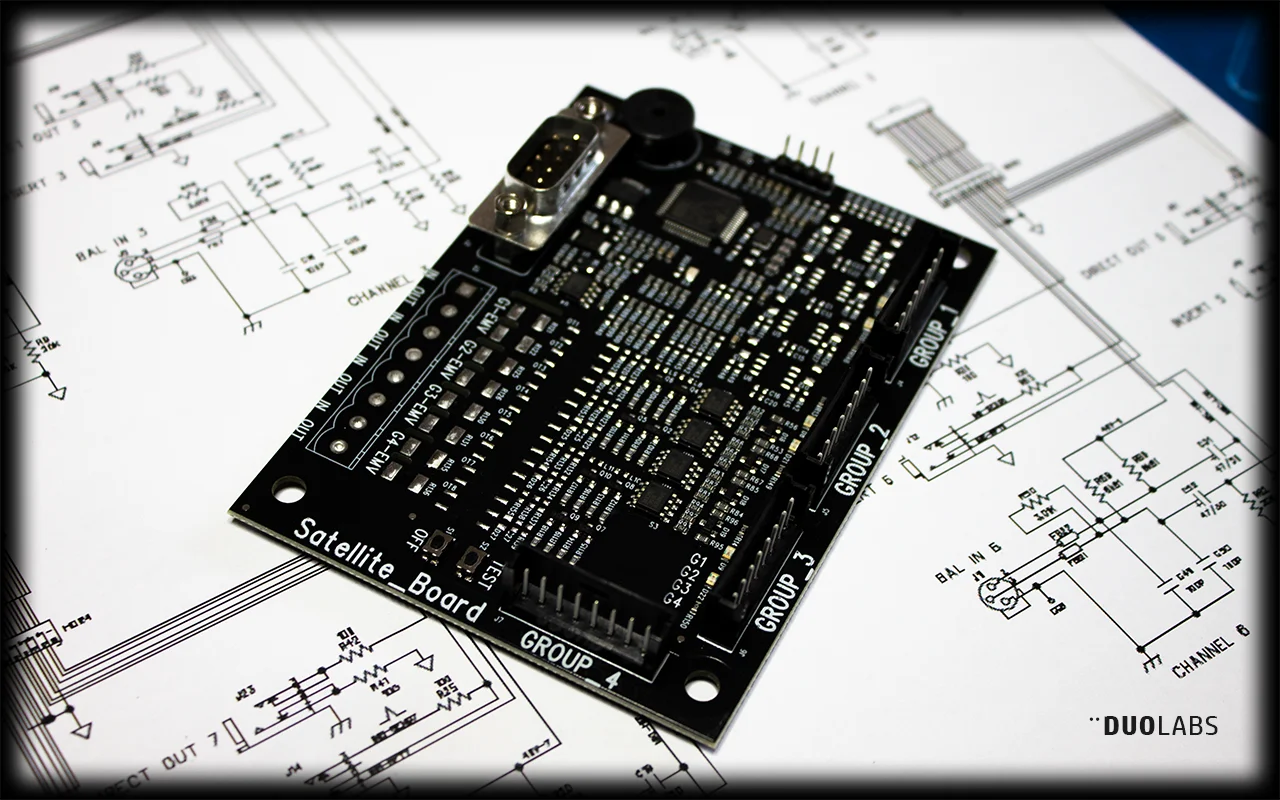

Cost analysis

We perform a targeted cost analysis to achieve the best match with the client’s goals. Where appropriate, we propose product alternatives with different levels of investment and performance, leveraging novelty and the opportunities offered by recent, available technologies. We provide clear comparative scenarios (costs, timelines, benefits) for quick, informed decisions, optimizing budget and time-to-market.